Plastics professionals converge at Penn College

Published 05.19.2022

News

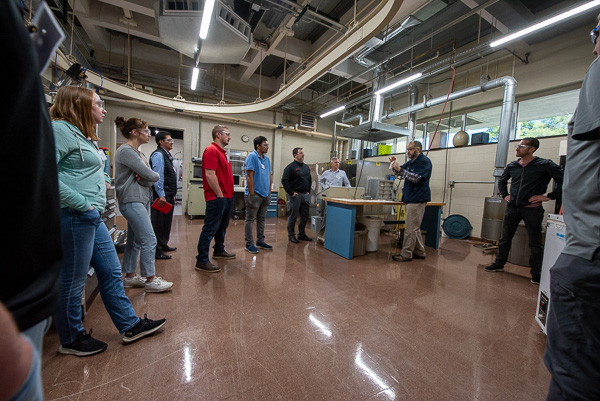

Plastics professionals from throughout North America enhanced their skills at a recent workshop hosted by Pennsylvania College of Technology and its renowned Plastics Innovation & Resource Center.

The two-day Rotational Molding & Advanced Materials Workshop offered a mix of lecture and hands-on instruction at the college’s Shell Polymers Rotational Molding Center of Excellence. Twenty-six individuals, representing 13 companies from seven states and Canada, learned the connection between material preparation, molding and final part quality.

R. Dru Laws, an industry leader and operations expert, served as workshop presenter. Laws is CEO of Halltech Systems in Rexburg, Idaho, and will soon join Brigham Young University as a manufacturing engineering professor.

R. Dru Laws, an industry leader and operations expert, served as workshop presenter. Laws is CEO of Halltech Systems in Rexburg, Idaho, and will soon join Brigham Young University as a manufacturing engineering professor.

The workshop earned rave reviews for delivering vital information, practical experience and networking opportunities.

“This workshop has helped me understand on a deeper level what I am doing on a daily basis and has already got me planning what to do when I get back to my team,” said Dakota Reiner, oven lead at Atlas Molding in Leola.

“The lab sessions were especially helpful because we took the information learned in class and put it into practice,” remarked Savannah Todd, designer engineer II at Yeti Coolers in Austin, Texas.

“It helped me gain a firmer rotational molding foundation, both theoretical and practical. I also learned from and networked with professionals from other companies,” said Parker Reneau, research engineer for the Cytec Solvay Group in Stamford, Connecticut.

“It has helped me understand more about how the process works and how I can help my company grow,” added Matt Schmalz, production supervisor at Scientific Plastics in Kansas City, Kansas.

Penn College workshop facilitators included Christopher J. Gagliano, PIRC project manager; Nathan A. Rader-Edkin, PIRC program manager; Jose M. Perez, instructor of plastics & polymer technology; and Gary E. McQuay, part-time instructor of plastics & polymer technology.

M. Holland Co. in Northbrook, Illinois, served as platinum sponsor.

The PIRC is one of the top plastics technology centers in the nation for research, development and education related to injection molding, extrusion, blow molding, rotational molding and thermoforming. To learn more, call 570-321-5533.

Penn College is one of six institutions nationwide offering plastics degrees that are accredited by the Engineering Technology Accreditation Commission of ABET. Students may seek a bachelor’s degree in plastics & polymer engineering technology or an associate degree in plastics & polymer technology.

For information about those and other majors within the School of Engineering Technologies, call 570-327-4520.

Penn College is a national leader in applied technology education. Email the Admissions Office or call toll-free 800-367-9222.

The two-day Rotational Molding & Advanced Materials Workshop offered a mix of lecture and hands-on instruction at the college’s Shell Polymers Rotational Molding Center of Excellence. Twenty-six individuals, representing 13 companies from seven states and Canada, learned the connection between material preparation, molding and final part quality.

R. Dru Laws, an industry leader and operations expert, served as workshop presenter. Laws is CEO of Halltech Systems in Rexburg, Idaho, and will soon join Brigham Young University as a manufacturing engineering professor.

R. Dru Laws, an industry leader and operations expert, served as workshop presenter. Laws is CEO of Halltech Systems in Rexburg, Idaho, and will soon join Brigham Young University as a manufacturing engineering professor.The workshop earned rave reviews for delivering vital information, practical experience and networking opportunities.

“This workshop has helped me understand on a deeper level what I am doing on a daily basis and has already got me planning what to do when I get back to my team,” said Dakota Reiner, oven lead at Atlas Molding in Leola.

“The lab sessions were especially helpful because we took the information learned in class and put it into practice,” remarked Savannah Todd, designer engineer II at Yeti Coolers in Austin, Texas.

“It helped me gain a firmer rotational molding foundation, both theoretical and practical. I also learned from and networked with professionals from other companies,” said Parker Reneau, research engineer for the Cytec Solvay Group in Stamford, Connecticut.

“It has helped me understand more about how the process works and how I can help my company grow,” added Matt Schmalz, production supervisor at Scientific Plastics in Kansas City, Kansas.

Penn College workshop facilitators included Christopher J. Gagliano, PIRC project manager; Nathan A. Rader-Edkin, PIRC program manager; Jose M. Perez, instructor of plastics & polymer technology; and Gary E. McQuay, part-time instructor of plastics & polymer technology.

M. Holland Co. in Northbrook, Illinois, served as platinum sponsor.

The PIRC is one of the top plastics technology centers in the nation for research, development and education related to injection molding, extrusion, blow molding, rotational molding and thermoforming. To learn more, call 570-321-5533.

Penn College is one of six institutions nationwide offering plastics degrees that are accredited by the Engineering Technology Accreditation Commission of ABET. Students may seek a bachelor’s degree in plastics & polymer engineering technology or an associate degree in plastics & polymer technology.

For information about those and other majors within the School of Engineering Technologies, call 570-327-4520.

Penn College is a national leader in applied technology education. Email the Admissions Office or call toll-free 800-367-9222.