Penn College first in U.S. higher education to get innovative welder

Published 01.18.2019

Pennsylvania College of Technology is partnering with Cambridge Vacuum Engineering Inc. to bring electron beam welding to the curriculum of its welding and metal fabrication program.

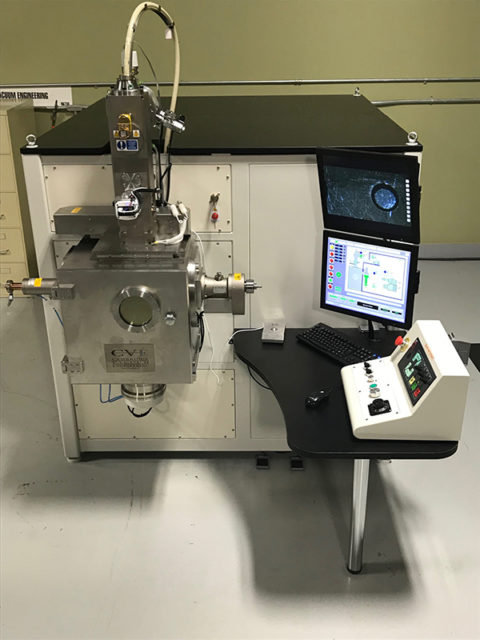

A 60kV electron beam welder from CVE, a Cambridge, England-based, company with a U.S. sales and support office, will be used by the college in its soon-to-be expanded welding instructional facility in the Lycoming Engines Metal Trade Center. This is the first electron beam welder placed by the company in any college or university within the United States, and one of only a few in higher-education institutions worldwide.

The welder will be installed in the fall of 2019, immediately enabling the college to enhance the majors offered within the welding and metal fabrication program, providing exceptional opportunities for Penn College students.

The need for electron beam welder technicians is increasing in industry; the partnership with CVE will help Penn College satisfy that demand. Electron beam welding has become a vital technology in the aerospace, automotive, energy, medical, semiconductor and military industries.

“This equipment is made for hands-on practice, and we are thrilled to team with our friends at Cambridge Vacuum Engineering Inc. to bring the equipment they have developed to higher education,” said Loni N. Kline, the college’s vice president for institutional advancement. “We are thrilled with the company’s generosity and by this partnership.”

“Electron Beam Welding has a strong industrial presence globally however exposure to the EB welding process has generally been limited to companies with their own EB welding systems,” said Tony Slater, technical sales manager for CVE Inc. USA. “The demand for new and skilled operators is always present so it’s an exciting prospect to have Penn College be the first to offer a course with EB welding to students.

“Aside from the conventional welding aspects, this would also open up research into areas such as material joining properties, dissimilar metals, Surfi-Sculpt and surface modification, to name a few. We are delighted to be teaming up with Penn College, as they have an amazing facility and vision to educate students in a practical and forward-thinking environment.”

“The addition of this unique, advanced welding technology will be of great benefit to our students,” added David Cotner, dean of industrial, computing and engineering technologies. “It will provide them with hands-on training and education in yet another aspect of the welding industry, allowing them to be real-world ready from Day One on the job.”

According to CVE’s website, the welder being placed at Penn College is “commonly used for the manufacture of small components including battery cans, medical components, aneroid capsules, latches, bellows, relays and electronic parts including transducers. The low heat input means that sensitive internal electronics packages may be sealed in the device without harm. Applications in the automotive industry include airbag inflators, gearbox components, transmission parts and turbocharger shaft wheel assemblies.”

Construction has commenced at Penn College on the welding expansion project. Made possible in part by a $2 million grant provided by the U.S. Department of Commerce’s Economic Development Administration, the expansion will increase the size of welding-related instructional space in the Lycoming Engines Metal Trades Center by approximately 35,000 square feet. Expanding will also allow the welding program to grow the curriculum and enroll up to 60 more students annually. The program has had a waiting list for a number of years.

Welding typically ranks near the top for program enrollments at Penn College. The college offers a bachelor’s degree in welding and fabrication engineering technology, an associate degree in welding technology, an associate degree in metal fabrication technology, and a certificate in welding.

Penn College is a national leader in applied technology education. For more, email the Admissions Office or call toll-free 800-367-9222.