Attendees Add to Toolkit at Heavy-Gauge Thermoforming Workshop

Published 07.02.2018

News

Student News

Faculty & Staff

Polymer Engineering

Workforce Development

PIRC

Industrial, Computing & Engineering Technologies News

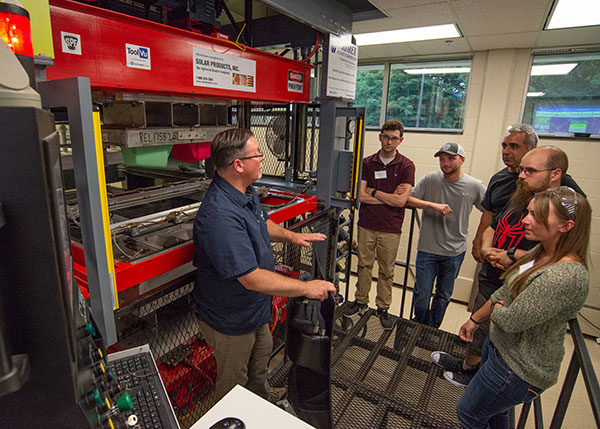

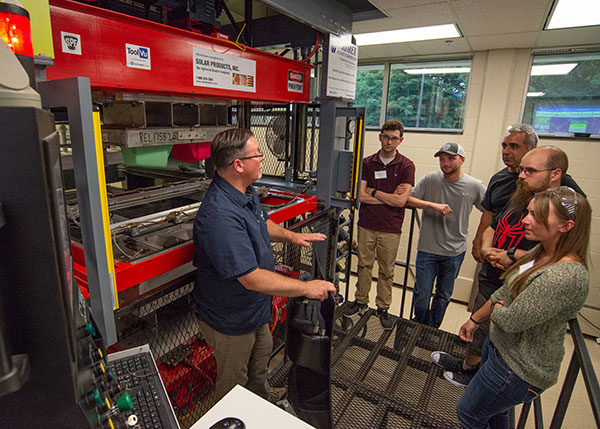

The Plastics Innovation & Resource Center at Pennsylvania College of Technology recently hosted 11 industry professionals from six states for its Ninth Annual National Hands-On Heavy-Gauge/Sheet-Fed Thermoforming Workshop.

The three-day program featured presentations from renowned experts and hands-on instruction in forming, trimming, assembly, techniques, materials, tooling, diagnostics, and machine maintenance and safety.

“The PIRC provides a unique opportunity to present both theory and practice in heavy-gauge thermoforming by allowing the participants to use their classroom instruction on a state-of-the-art former,” said keynoter James “Jay” M. Waddell, from Plastics Concepts & Innovations LLC. “Participants were able to use multiple forming techniques and learned how to adjust the equipment to achieve the best results.”

Attendees – who represented eight companies in Colorado, Michigan, New York, Pennsylvania, Tennessee, Texas and Mexico – expressed their satisfaction in a follow-up survey.

Attendees – who represented eight companies in Colorado, Michigan, New York, Pennsylvania, Tennessee, Texas and Mexico – expressed their satisfaction in a follow-up survey.

“The workshop covered all aspects of thermoforming in a very detailed manner,” said David Arcaute, process engineer for Corvac Composites LLC in San Marcos, Texas.

Tom Herbert, of Bo-Mer Plastics in Auburn, New York, added, “I think you all did a phenomenal job.”

In addition to Waddell, globally respected industry specialists shared their expertise and experiences: Roger C. Kipp, of Roger C. Kipp & Associates; Vijay Kudchadkar, representing Compu; and Terrence Woldorf, of CMT Materials Inc.

Penn College faculty, staff and students facilitated a variety of sessions, including Kirk M. Cantor, professor of plastics and polymer technology; Joseph E. LeBlanc, assistant professor of physics; Christopher J. Gagliano, program manager for the college’s Thermoforming Center of Excellence; and Brennan B. Wodrig, PIRC laboratory supervisor and project coordinator.

Assisting throughout were plastics and polymer engineering technology majors Noah L. Martin, of South Williamsport, and Wilson R. Michael, of Hughesville.

The PIRC is one of the top plastics technology centers in the nation for research, development and education related to injection molding, extrusion, blow molding, rotational molding and thermoforming. Its Thermoforming Center of Excellence is a technical resource offering independent, hands-on applied research and development to the thermoforming community.

To learn more about the PIRC and the Thermoforming Center of Excellence, call 570-321-5533.

Penn College is one of a half-dozen colleges in the country offering plastics degree programs accredited by the Engineering Technology Accreditation Commission of ABET. For information on plastics degrees and other majors within the School of Industrial, Computing & Engineering Technologies, call 570-327-4520.

For more about Penn College, a national leader in applied technology education and workforce development, email the Admissions Office or call toll-free 800-367-9222.

The three-day program featured presentations from renowned experts and hands-on instruction in forming, trimming, assembly, techniques, materials, tooling, diagnostics, and machine maintenance and safety.

“The PIRC provides a unique opportunity to present both theory and practice in heavy-gauge thermoforming by allowing the participants to use their classroom instruction on a state-of-the-art former,” said keynoter James “Jay” M. Waddell, from Plastics Concepts & Innovations LLC. “Participants were able to use multiple forming techniques and learned how to adjust the equipment to achieve the best results.”

Attendees – who represented eight companies in Colorado, Michigan, New York, Pennsylvania, Tennessee, Texas and Mexico – expressed their satisfaction in a follow-up survey.

Attendees – who represented eight companies in Colorado, Michigan, New York, Pennsylvania, Tennessee, Texas and Mexico – expressed their satisfaction in a follow-up survey.“The workshop covered all aspects of thermoforming in a very detailed manner,” said David Arcaute, process engineer for Corvac Composites LLC in San Marcos, Texas.

Tom Herbert, of Bo-Mer Plastics in Auburn, New York, added, “I think you all did a phenomenal job.”

In addition to Waddell, globally respected industry specialists shared their expertise and experiences: Roger C. Kipp, of Roger C. Kipp & Associates; Vijay Kudchadkar, representing Compu; and Terrence Woldorf, of CMT Materials Inc.

Penn College faculty, staff and students facilitated a variety of sessions, including Kirk M. Cantor, professor of plastics and polymer technology; Joseph E. LeBlanc, assistant professor of physics; Christopher J. Gagliano, program manager for the college’s Thermoforming Center of Excellence; and Brennan B. Wodrig, PIRC laboratory supervisor and project coordinator.

Assisting throughout were plastics and polymer engineering technology majors Noah L. Martin, of South Williamsport, and Wilson R. Michael, of Hughesville.

The PIRC is one of the top plastics technology centers in the nation for research, development and education related to injection molding, extrusion, blow molding, rotational molding and thermoforming. Its Thermoforming Center of Excellence is a technical resource offering independent, hands-on applied research and development to the thermoforming community.

To learn more about the PIRC and the Thermoforming Center of Excellence, call 570-321-5533.

Penn College is one of a half-dozen colleges in the country offering plastics degree programs accredited by the Engineering Technology Accreditation Commission of ABET. For information on plastics degrees and other majors within the School of Industrial, Computing & Engineering Technologies, call 570-327-4520.

For more about Penn College, a national leader in applied technology education and workforce development, email the Admissions Office or call toll-free 800-367-9222.